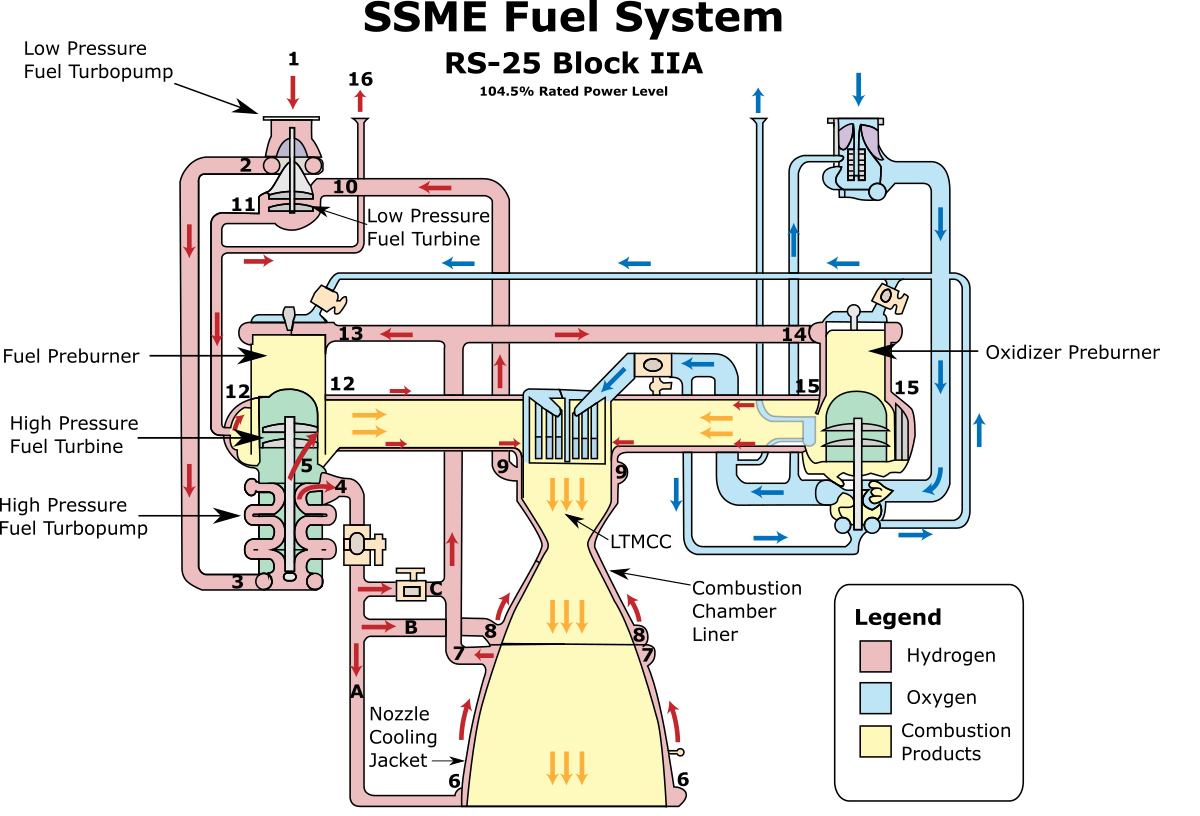

Figure 1.1.1: SSME Fuel System Schematic [1, 2]

The SSME fuel system performs two functions:

a. Route high-pressure hydrogen to the engine’s three combustion chambers.

b. Route cryogenic hydrogen to regeneratively cool the walls of the combustion chambers and the nozzle jacket.

Liquid hydrogen enters the Low Pressure Fuel Turbopump (Station 1) from the External Tank. This pump raises the pressure of the incoming fluid to a modest level before routing it to the High Pressure Fuel Turbopump (HPFTP) at Station 3 where the pressure is raised to a level suitable for combustion. A small quantity of hydrogen (Station 5) flows through the seals of the HPFTP in order to cool the High Pressure Fuel Turbine. After cooling the turbine bearings, this hydrogen is mixed into the combustion gases departing the turbine exit.

After departing the HPFTP at Station 4, the hydrogen flow spits into three branches. Branch “A” runs to the nozzle cooling jacket (Stations 6-7). This heat exchanger consists of 1080 brazed A286 stainless steel tubes running along the length of the nozzle.[67] It ensures the hot exhaust plume does not melt the nozzle wall. Cold hydrogen enters the cooling jacket at Station 6, flows up the nozzle wall, and exits the cooling jacket at Station 7. From here, the flow splits yet again and is routed to the Fuel Preburner Hydrogen Inlet (Station 13) and the Oxidizer Preburner Hydrogen Inlet (Station 14).

The second branch departing the HPFTP (Branch “B”) is used to cool the walls of the Large Throat Main Combustion Chamber (LTMCC). Cold hydrogen enters the combustion chamber liner at Station 8. It flows up the walls of the liner through 430 rectangular channels [68] and exits at Station 9. From here the hydrogen is routed to Station 10 in order to drive the Low Pressure Fuel Turbine. The Low Pressure Fuel Turbine powers the Low Pressure Fuel Turbopump, thus sustaining the overall mass flow rate of liquid hydrogen into the system. After departing the Low Pressure Fuel Turbine at Station 11, the flow proceeds to Station 12 where it enters cooling passages designed to regulate the temperature of the Fuel Preburner. Hydrogen flows down these cooling passages all the way to the LTMCC.

In a similar manner, a small quantity of hydrogen is utilized to cool the Oxidizer Preburner. Hydrogen branches off from the Oxidizer Preburner Inlet at Station 14 and flows into the Oxidizer Preburner Coolant Passage (Station 15). From here the flow proceeds directly into the LTMCC.

Some of the hydrogen departing the Low Pressure Fuel Turbine at Station 11 is routed back to the external hydrogen tank to provide ullage pressure (Station 16).

The third branch departing the HPFTP (Branch “C”) merges with the outflow from the nozzle cooling jacket (Station 7) and is routed to the Fuel and Oxidizer Preburner Inlets (Stations 13 and 14).

Table 1.1.1 displays several key thermodynamic properties of the flow as it progresses through these stations. The mass flow rates, temperatures, and pressures listed below were tabulated from Reference [2]. Densities and enthalpies were calculated utilizing the procedure described in Section 2.2.

| Station | Component | Mass Flow $kg/s$ | Temperature $K$ | Pressure $MPa$ | Density $\frac{kg}{m^3}$ | Enthalpy $kJ/kg$ |

|---|---|---|---|---|---|---|

| 1 | Low Pressure Fuel Turbopump Inlet | 70.3 | 20.4 | 0.21 | 70.38 | -4449 |

| 2 | Low Pressure Fuel Turbopump Exit | 70.3 | 23.7 | 2.05 | 69.07 | -4412 |

| 3 | High Pressure Fuel Turbopump Inlet | 70.3 | 23.7 | 1.72 | 68.58 | -4401 |

| 4 | High Pressure Fuel Turbopump Exit | 67.6 | 51.5 | 41.07 | 78.83 | -3749 |

| 5 | High Pressure Fuel Turbine Coolant | 2.7 | 51.5 | 41.07 | 78.82 | -3748 |

| 6 | Nozzle Cooling Jacket Inlet | 21.1 | 51.5 | 38.78 | 77.75 | -3769 |

| 7 | Nozzle Cooling Jacket Exit | 21.1 | 330.9 | 37.37 | 31.99 | -1424 |

| 8 | Combustion Chamber Liner Inlet | 13.2 | 52.0 | 38.93 | 77.57 | -3762 |

| 9 | Combustion Chamber Liner Exit | 13.2 | 264.8 | 30.62 | 25.08 | -819 |

| 10 | Low Pressure Fuel Turbine Inlet | 13.2 | 264.8 | 29.08 | 24.36 | -827 |

| 11 | Low Pressure Fuel Turbine Exit | 13.2 | 255.4 | 21.85 | 21.50 | -1001 |

| 12 | Fuel Pre-Burner Coolant Passages | 7.7 | 255.4 | 21.85 | 21.50 | -1001 |

| 13 | Fuel Pre-Burner H2 Inlet | 34.9 | 148.2 | 36.61 | 42.42 | -2503 |

| 14 | Oxidizer Pre-Burner H2 Inlet | 19.1 | 148.2 | 36.61 | 42.42 | -2503 |

| 15 | Oxidizer Pre-Burner Coolant Passages | 5.0 | 255.4 | 21.85 | 21.50 | -1001 |

| 16 | External Hydrogen Tank Ullage Gas Supply | 0.5 | 255.4 | 21.85 | 21.50 | -1001 |

| Station | Component | Mass Flow $lbm/s$ | Temperature $F$ | Pressure $psi$ | Density $\frac{lbm}{ft^3}$ | Enthalpy $BTU/lbm$ |

|---|---|---|---|---|---|---|

| 1 | Low Pressure Fuel Turbopump Inlet | 155 | -423 | 30 | 4.39 | -1912.7 |

| 2 | Low Pressure Fuel Turbopump Exit | 155 | -417 | 298 | 4.31 | -1897 |

| 3 | High Pressure Fuel Turbopump Inlet | 155 | -417 | 250 | 4.28 | -1892.1 |

| 4 | High Pressure Fuel Turbopump Exit | 149 | -367 | 5956 | 4.92 | -1611.7 |

| 5 | High Pressure Fuel Turbine Coolant | 6 | -367 | 5956 | 4.92 | -1608 |

| 6 | Nozzle Cooling Jacket Inlet | 46.6 | -367 | 5624 | 4.85 | -1620.5 |

| 7 | Nozzle Cooling Jacket Exit | 46.6 | 136 | 5420 | 2.00 | -612.3 |

| 8 | Combustion Chamber Liner Inlet | 29 | -366 | 5647 | 4.84 | -1617.2 |

| 9 | Combustion Chamber Liner Exit | 29 | 17 | 4441 | 1.57 | -352.2 |

| 10 | Low Pressure Fuel Turbine Inlet | 29 | 17 | 4217 | 1.52 | -355.5 |

| 11 | Low Pressure Fuel Turbine Exit | 29 | 0 | 3169 | 1.34 | -430.6 |

| 12 | Fuel Preburner Coolant Passages | 17 | 0 | 3169 | 1.34 | -430.6 |

| 13 | Fuel Preburner H2 Inlet | 77 | -193 | 5310 | 2.65 | -1075.9 |

| 14 | Oxidizer Preburner H2 Inlet | 42 | -193 | 5310 | 2.65 | -1075.9 |

| 15 | Oxidizer Preburner Coolant Passages | 11 | 0 | 3169 | 1.34 | -430.6 |

| 16 | External Hydrogen Tank Ullage Gas Supply | 1 | 0 | 3169 | 1.34 | -430.6 |